Bulk order discounts offer a practical way to reduce costs in high-volume molding. By purchasing in bulk, you can save up to 15% on raw materials through direct supplier relationships. Economies of scale further amplify savings. For example, increasing production volume can lower per-unit costs by as much as 30%. Fixed expenses, like equipment maintenance, get distributed across more units, reducing overall costs. To maximize these benefits, strategic planning is essential. Align your production needs with bulk purchasing to unlock significant savings and enhance efficiency.

Bulk order discounts are price reductions offered by suppliers when you purchase large quantities of a product. These discounts reward you for committing to higher volumes, making it a win-win situation for both you and the supplier. For example, if you order 10,000 units of a molding material instead of 1,000, the supplier may lower the price per unit. This reduction can significantly impact your overall costs, especially in high-volume manufacturing.

To better understand how these discounts work, consider the following table:

| Evidence Description | Impact on Cost Savings |

|---|---|

| Bulk order discounts on injection molding machines | Significant reduction in upfront investment |

| Economies of scale achieved through bulk purchasing | Lower unit costs compared to individual purchases |

| Improved operational efficiency from strategic planning | Enhanced resource allocation and reinvestment of savings |

This table highlights how bulk order discounts not only reduce costs but also improve efficiency. By leveraging these discounts, you can allocate resources more effectively and reinvest the savings into other areas of your business.

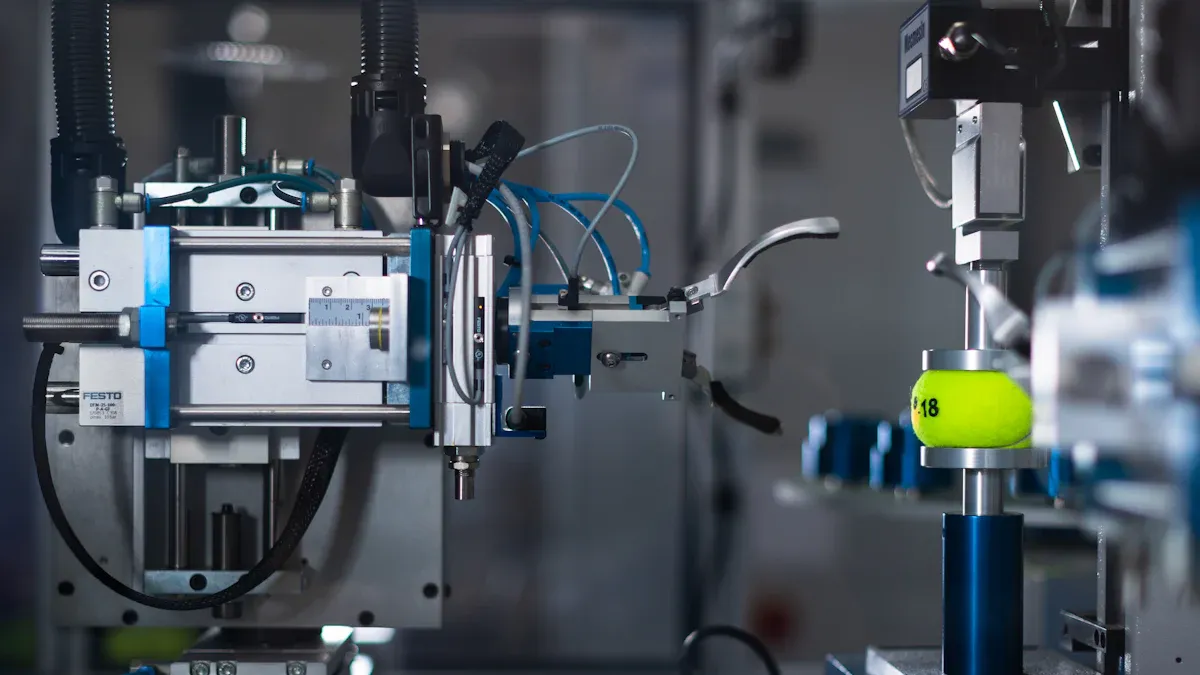

In the molding industry, bulk order discounts play a crucial role in maintaining cost efficiency. Molding processes often involve high upfront costs, such as purchasing raw materials, maintaining equipment, and managing labor. By ordering in bulk, you can lower the per-unit cost of materials, which directly impacts your profit margins.

For instance, when you buy molding materials in large quantities, suppliers often provide better rates. This allows you to produce more units at a lower cost. Additionally, bulk purchasing helps you achieve economies of scale. Fixed costs, like machine maintenance, get spread across a larger number of units, reducing the cost per unit.

Another advantage of bulk order discounts is improved operational efficiency. When you plan your purchases strategically, you can avoid frequent reordering and reduce downtime. This ensures a smoother production process and helps you meet customer demands more effectively.

Tip: To maximize the benefits of bulk order discounts, align your production schedule with your purchasing strategy. This ensures that you always have the right materials in stock without overloading your inventory.

Understanding bulk order discounts is essential for anyone in the molding industry. By taking advantage of these discounts, you can reduce costs, improve efficiency, and enhance your overall profitability.

Economies of scale play a vital role in reducing costs in high-volume molding. When you increase production volume, fixed costs, such as tooling and equipment maintenance, get distributed across more units. This reduces the cost per unit significantly. For example, producing thousands of parts allows you to spread the initial mold costs over a larger quantity, making each piece more affordable.

High production volumes also enable operational efficiencies. Automation and streamlined processes become more feasible, further lowering costs. Bulk production discounts from suppliers amplify these savings, making it easier for you to achieve cost efficiency.

Tip: To maximize economies of scale, focus on optimizing your production processes and negotiating better rates with suppliers for large orders.

Volume discounts directly impact your per-unit costs. By ordering in bulk, you can negotiate lower prices with suppliers, which reduces the overall cost of materials. For instance, if you purchase 500 units of a material at a 15% discount, you save a significant amount compared to buying smaller quantities.

Here’s a simple formula for calculating cost savings:

(Regular Price - Discounted Price) × Quantity Ordered

Consider this example:

- A construction company saves $6,250 by ordering 500 bags of cement at a 15% discount from a regular price of $50 per bag.

- Similarly, an office manager saves $1,000 by purchasing 100 reams of printer paper at a discounted rate of $40 per ream instead of $50.

In molding, increasing production volume reduces price-per-piece costs. The table below illustrates how production volume impacts cost reduction:

| Production Volume | Cost Reduction Impact |

|---|---|

| Low (25 pieces) | Higher per-unit cost |

| Medium (up to 25,000 parts) | Reduced per-unit cost due to amortization of tooling costs |

| High (thousands of parts) | Significant cost savings as tooling costs are spread across more units |

By leveraging volume discounts, you can lower your expenses and allocate resources more effectively.

Bulk orders not only reduce costs but also improve your profit margins. When you pay less for materials, you can either pass the savings on to your customers or retain them to boost profitability. High production volumes also allow you to negotiate better terms with suppliers, further enhancing your margins.

For example, supplier negotiations for bulk orders often result in lower unit prices. This gives you a competitive edge in pricing your products. Additionally, operational efficiencies, such as reduced downtime and streamlined workflows, contribute to higher profit margins.

Note: To enhance your profit margins, align your bulk purchasing strategy with your production goals. This ensures you maximize savings while maintaining product quality.

By understanding and implementing these strategies, you can unlock the full potential of bulk order discounts. This approach not only reduces costs but also positions your business for long-term success.

Minimum order quantities (MOQs) significantly impact your bulk order savings. Suppliers often set MOQs to ensure cost efficiency in production and logistics. For you, this means balancing the benefits of volume discounts with the risks of overstocking. Materials sold in fixed amounts can lead to excess inventory if not managed properly. For example, inventory costs can account for 12% to 34% of your total expenses. Mismanaging MOQs may result in storage issues, obsolescence, and increased costs.

Efficient stock management helps you avoid these pitfalls. By aligning your MOQs with production needs, you can prevent stockouts and reduce holding costs. The table below highlights how MOQs influence savings:

| Factor | Impact on Bulk Order Savings |

|---|---|

| Efficient Stock Management | Prevents stockouts and ensures a minimum level of demand. |

| Reduced Inventory Holding Costs | Avoids excess inventory and associated costs. |

| Streamlined Supply Chain | Optimizes material flow and ensures timely production. |

| Cost Savings | Leads to volume discounts and lower unit costs. |

| Production Efficiency | Optimizes production processes and reduces setup time. |

Understanding MOQs allows you to maximize savings while maintaining production efficiency.

Negotiating bulk order discounts is a critical strategy for reducing costs. Open communication with suppliers fosters trust and can lead to better deals. For instance, analyzing market trends, such as a housing boom, can help you predict demand and commit to larger orders. This proactive approach often results in lower prices per unit.

Building strong supplier relationships also ensures long-term benefits. Retailers who maintain consistent communication often secure favorable terms. Additionally, when raw materials face potential scarcity, collaborating with suppliers to lock in prices protects you from market fluctuations. These strategies not only enhance your savings but also strengthen your supply chain.

To succeed in negotiating bulk order discounts, focus on understanding your supplier’s discount structure. Many suppliers offer threshold discounts, where higher order volumes unlock greater savings. By aligning your purchasing strategy with these thresholds, you can achieve significant cost reductions.

Material costs and production efficiency directly influence your ability to save through bulk orders. Choosing the right materials for your production needs is essential. For example, aluminum molds are ideal for short runs (<10,000 shots), while P20 steel suits medium runs (10,000–100,000 shots). For high-volume production, H13 or S7 steel offers durability and cost efficiency.

To further optimize savings, monitor material waste and streamline your processes. Implementing just-in-time inventory management reduces excess stock and minimizes waste. Strengthening oversight of design and manufacturing processes also enhances efficiency. Regular design reviews and standardizing components across product lines can significantly lower costs.

By combining these strategies, you can reduce material expenses and improve production efficiency, maximizing the benefits of volume discounts.

To maximize savings, you need to create pricing strategies that align with your bulk purchasing goals. One effective approach is quantity-based pricing, where discounts increase as order volumes grow. This incentivizes larger purchases and helps you secure better deals. Another option is tiered pricing, which offers predefined price points for specific order quantities. For example, ordering 10,000 units might unlock a lower price tier compared to 5,000 units. Dynamic discounting is another strategy that adjusts prices based on factors like order frequency or customer loyalty, ensuring flexibility in your pricing model.

| Pricing Model | Description |

|---|---|

| Quantity-Based Pricing | Discounts are applied based on the volume of items ordered, incentivizing larger order quantities. |

| Tiered Pricing | Pricing is segmented into tiers, with each tier offering a different price point for predefined quantities or contract commitments. |

| Dynamic Discounting | Discounts are applied dynamically based on various factors such as order volume, order frequency, or customer loyalty. |

By implementing these strategies, you can optimize your fixed wholesale pricing and encourage repeat orders, ultimately boosting your profitability.

Effective inventory management is crucial when you implement a wholesale discount strategy. Overstocking can lead to increased storage costs, while understocking risks production delays. Accurate quantity estimation ensures you maintain the right balance. For instance, a retail company that adopted bulk ordering and inventory control saw increased profitability by reducing order frequency and saving resources.

Here’s how you can manage inventory effectively:

1. Estimate quantities accurately to avoid overstocking or understocking.

2. Use strategic inventory management to lower expenses and ensure sufficient stock.

3. Form wholesale partnerships to secure better pricing and consistent supply.

These practices not only reduce costs but also streamline your operations, allowing you to fully leverage volume discounts.

Strong supplier relationships are key to sustaining cost savings. By consolidating suppliers, you can negotiate better terms and secure fixed wholesale pricing. This approach reduces coordination issues and enhances long-term alignment. Suppliers often retain resources during sales declines to maintain relationships with loyal customers, ensuring stability in your supply chain.

For example, consolidating suppliers allows you to achieve significant cost reductions through rebates and discounts. It also simplifies operations and ensures stable pricing over time. Building trust with your suppliers fosters collaboration, enabling you to implement a wholesale discount strategy that benefits both parties.

Tip: Regular communication with suppliers strengthens partnerships and helps you stay informed about new opportunities for savings.

A mid-sized manufacturing company specializing in injection molding faced rising production costs. The company decided to explore volume discounts by ordering raw materials in bulk. After negotiating with suppliers, they secured a 20% discount on resin, their primary material. This decision significantly reduced their per-unit material costs.

The company also optimized its production schedule to align with bulk purchasing. By producing larger batches, they minimized machine setup times and reduced downtime. These changes improved efficiency and lowered operational costs. Over a year, the company saved $50,000, which they reinvested in upgrading equipment and expanding their product line.

This case highlights how volume discounts can transform your business. By planning strategically and working closely with suppliers, you can achieve substantial cost savings and improve your bottom line.

High-volume manufacturing offers valuable insights into maximizing savings. One key lesson is the importance of streamlining processes. Efficient workflows reduce waste and improve productivity. For example, automating repetitive tasks can save time and resources.

Another lesson is the value of strong supplier relationships. Long-term partnerships often lead to better deals and consistent quality. You should communicate regularly with your suppliers to stay informed about new opportunities for savings.

Finally, aligning production with demand ensures you avoid overproduction and excess inventory. This approach minimizes storage costs and maximizes the benefits of volume discounts. By applying these lessons, you can enhance efficiency and profitability in your operations.

Tip: Start small by testing bulk orders with a single product line. Gradually expand as you gain confidence in managing larger volumes.

Bulk order discounts offer a powerful way to achieve cost savings in molding. By reducing per-unit costs, they help you improve profit margins and allocate resources more effectively. To maximize these benefits, focus on strategic actions like negotiating supplier agreements and managing inventory efficiently.

Economies of scale amplify these savings by spreading fixed costs across larger production volumes. By implementing these strategies, you can enhance efficiency and position your business for long-term success.

A wholesale discount is a price reduction offered to wholesale customers who buy in bulk. Suppliers provide these discounts to encourage larger orders. For example, purchasing 1,000 units instead of 100 often results in a lower price per unit.

Percentage-based discounts allow wholesale customers to save a specific percentage on their total order. For instance, a 10% discount on a $10,000 order saves you $1,000. This type of discount is common in wholesale transactions.

Yes, many suppliers have discount policies tailored for wholesale customers. These policies often include tiered pricing, where higher order volumes unlock greater savings. Understanding these policies helps you maximize your cost savings.

To negotiate better discounts, build strong relationships with suppliers. Show commitment by placing consistent orders. Research market trends to understand pricing and use this knowledge to negotiate favorable terms.

Yes, wholesale discounts reduce your per-unit costs. Lower costs mean higher profit margins. By aligning your purchasing strategy with these discounts, you can enhance profitability while maintaining competitive pricing.