Recycled plastics play a vital role in sustainable practices within injection molding. By reusing materials, you can significantly reduce waste while conserving valuable resources. Optimized recycling processes in injection molding have already cut manufacturing waste by 20%. This shows how sustainable practices can transform the industry. Using recycled plastics not only reduces the burden on landfills but also limits the extraction of natural resources. Every step you take toward recycling contributes to a greener future and a more efficient manufacturing process.

Recycling plays a critical role in reducing material waste that ends up in landfills and oceans. By reusing plastics, you help divert significant amounts of waste from these areas. This process not only minimizes the environmental impact but also prevents harmful gases, like methane, from being released into the atmosphere. For example:

- Recycling plastic reduces landfill use by converting recyclable materials into new products.

- It removes waste from the environment, ensuring cleaner ecosystems.

- Products designed for recycling or repair further support this effort.

Systemic changes, such as banning single-use plastics and improving recycling infrastructure, are essential for long-term success. These measures ensure that sustainable injection molding contributes to a cleaner planet.

Recycling conserves valuable natural resources by reducing the need for virgin materials. When you use recycled plastics in injection molding, you help preserve raw materials like petroleum and natural gas. This approach supports sustainability by promoting a circular economy.

| Benefit | Description |

|---|---|

| Resource Conservation | The use of recycled plastics conserves natural resources by reducing the need for virgin materials. |

| Lower Demand for Virgin Components | Incorporating recycled plastics reduces the reliance on new materials, promoting a circular economy. |

By choosing recycled materials, you actively reduce the strain on Earth's finite resources. This practice ensures that future generations can benefit from a healthier environment.

Factories that use recycled plastics in injection molding significantly lower their greenhouse gas emissions. For instance, facilities using PolyCycle PCR resin achieve up to a 70% reduction in emissions compared to those using virgin resin. This measurable improvement highlights the environmental impact of sustainable practices.

| Benefit | Description |

|---|---|

| Reduced Carbon Footprint | Injection molding with recycled plastics significantly lowers the carbon emissions associated with production. |

| Energy Usage Reduction | Sustainable materials in injection molding processes lead to lower energy consumption during production. |

By adopting sustainable injection molding, you contribute to a cleaner environment and help combat climate change. Lower emissions and reduced energy use make this approach a win-win for both manufacturers and the planet.

Recycled plastics are transforming the injection molding process by enabling the production of a wide range of eco-friendly products. You can find these materials in everyday items such as packaging, automotive components, and even furniture. This shift is driven by stricter environmental regulations and changing consumer preferences. Companies are investing in recycled and bio-based materials to meet these demands.

For example, many manufacturers now use recycled plastics to create durable outdoor furniture, reusable containers, and lightweight automotive parts. These products not only reduce waste but also demonstrate the versatility of recycled materials in injection molding. By choosing products made from recycled plastics, you support a circular economy and help reduce the environmental impact of manufacturing.

Several industries are setting benchmarks in sustainable injection molding by adopting recycled materials. The plastics industry, in particular, faces immense pressure to embrace recycling as a core practice. Companies like Essentra are leading the way by incorporating high percentages of recycled materials into their products. Essentra, for instance, produces components made from 98% recycled plastic, showcasing the practical application of sustainable injection molding.

Other sectors, such as automotive and consumer goods, are also making significant strides. Automakers are increasingly using recycled plastics to manufacture interior and exterior vehicle components. This approach not only reduces costs but also aligns with global sustainability goals. Similarly, consumer goods companies are prioritizing recycled materials to meet the growing demand for eco-friendly products.

Real-world examples highlight the benefits of using recycled materials in injection molding. A mid-sized manufacturing firm recently transitioned to recycled plastics and achieved a 15% reduction in production costs. This success was made possible through strategic planning, including a thorough assessment of existing processes and materials. Adjustments to mold design also played a crucial role in optimizing performance.

In-house recycling solutions have further enhanced efficiency for many companies. By reclaiming scrap material and reintroducing it into production, manufacturers have reduced waste and lowered costs. These efforts demonstrate how innovation and commitment to sustainability can drive tangible results in the injection molding industry.

| Section | Key Insights |

|---|---|

| Practical Steps | Transitioning to recycled plastics requires a strategic approach. |

| Mould Design Considerations | Adjustments to mold design optimize performance with recycled materials. |

| Cost Analysis | Initial investments may seem high, but long-term savings are significant. |

| Success Stories | A firm reduced production costs by 15% after adopting recycled materials. |

| Future Trends | Research is improving recycled materials, promising a sustainable future. |

By learning from these examples, you can better understand how to implement sustainable practices in your own operations. The injection molding process continues to evolve, offering new opportunities to reduce waste and conserve resources.

Using recycled materials in injection molding can significantly reduce costs while maintaining product quality. Material expenses often dominate the budget in manufacturing projects. By incorporating recycled plastics, you can lower these expenses without compromising structural integrity. For example:

- Recycled materials often cost less than virgin polymers.

- Strategic sourcing, such as forming partnerships with suppliers, can further enhance cost efficiency.

A cost analysis reveals that manufacturers who adopt recycled plastics save money in the long term. These savings stem from reduced raw material costs and optimized production processes. By choosing recycled materials, you not only cut expenses but also contribute to a more sustainable manufacturing ecosystem.

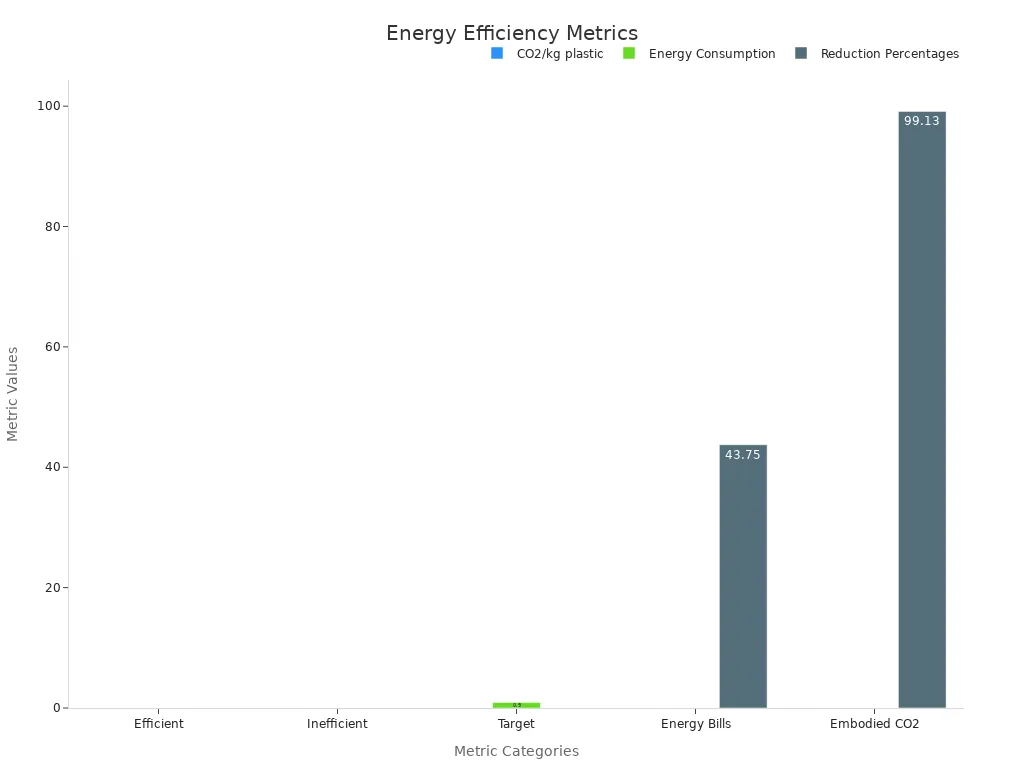

Recycled plastics make injection molding more energy-efficient. The production process for recycled materials consumes less energy compared to creating new polymers. This efficiency translates into lower energy bills and reduced environmental impact.

| Metric | Value |

|---|---|

| CO2 per kg plastic (efficient) | 0.0081 kg CO2 |

| CO2 per kg plastic (inefficient) | 0.0144 kg CO2 |

| Energy consumption (target) | 0.9 kWh/kg plastic |

| Reduction in energy bills | 43.75% |

| Reduction in embodied CO2 | Up to 99.13% |

By adopting energy-efficient injection molding practices, you can achieve measurable improvements in both cost and sustainability. This approach not only benefits your bottom line but also aligns with global efforts to conserve energy and reduce waste.

Recycled plastics play a crucial role in reducing the carbon footprint of manufacturing. The use of recycled materials requires less energy and fewer fossil fuels, leading to lower greenhouse gas emissions. A carbon footprint assessment highlights the following benefits:

| Benefit | Description |

|---|---|

| Reduced fossil fuel use | Less oil or petrol is required to create new plastics, leading to lower emissions. |

| Lower carbon emissions | The production of less plastic or reduced burning of plastic results in decreased carbon output. |

| Decreased energy use | Recycling processes are less energy-intensive compared to creating new polymers. |

By integrating recycled plastics into your injection molding processes, you actively contribute to reducing carbon emissions. This step not only helps combat climate change but also positions your business as a leader in sustainable manufacturing.

Maintaining consistent quality when using recycled plastics can be challenging. Variability in recyclates often arises due to regional and seasonal differences. However, you can overcome these challenges by applying advanced quality control methods. Analytical techniques like chromatography and spectroscopy, commonly used for virgin materials, also work effectively for recycled plastics. These methods ensure that the materials meet the required standards.

Automated systems further enhance quality control. They collect extensive data points to detect issues such as thin spots or inconsistencies in products. By integrating these systems into your processes, you can achieve higher precision and reliability.

| Evidence | Description |

|---|---|

| Analytical Methods | Chromatography and spectroscopy ensure consistent quality in recyclates. |

| Automated Systems | Automated tools detect quality issues like thin spots in products. |

| Variability Challenges | Regional and seasonal differences affect the quality of recyclates. |

By adopting these practices, you can ensure that recycled plastics meet the demands of sustainable material selection while maintaining product integrity.

Recycling and reusing plastic materials in injection molding introduces technical challenges. You may encounter issues such as material degradation caused by multiple heat cycles. This degradation impacts the mechanical properties of the final product. Contamination from impurities is another common problem, which can disrupt the molding process.

Other challenges include inconsistencies in melt flow characteristics and viscosities. These variations make it difficult to achieve uniform results. To address these limitations, you can implement advanced recycling techniques that improve material purity and performance. Regular testing and adjustments to processing parameters also help mitigate these issues.

By tackling these technical hurdles, you can strengthen the business case for sustainable injection molding.

Innovations in recycling and reusing scrap material are transforming injection molding. Advanced recycling techniques now allow you to process recyclable materials with greater efficiency. These methods reduce contamination and improve the quality of eco-friendly materials. For example, closed-loop systems enable you to recycle scrap material directly within your facility, supporting sustainable facility operations.

New technologies also enhance the production of eco-friendly products. Improved mold designs and material formulations optimize the use of recycled plastics. These innovations not only reduce waste but also lower energy consumption. By embracing these advancements, you can create a more sustainable manufacturing process and contribute to a greener future.

Tip: Investing in innovative solutions can help you stay ahead in the competitive market for eco-friendly products.

Recycled plastics are transforming injection molding into a more sustainable process. By using these materials, you reduce waste, conserve resources, and lower your carbon footprint. Manufacturers also benefit from cost savings and improved operational efficiency.

| Benefit Type | Description |

|---|---|

| Environmental | Reduces material waste and carbon footprint, conserves resources, and minimizes environmental impacts. |

| Economic | Lowers operational costs through energy-efficient processes and long-term cost savings. |

| Operational | Improves resource management, reduces downtime, and enhances supply chain resilience. |

Adopting recycled plastic materials supports a greener future. Your efforts contribute to a cleaner planet and a more sustainable manufacturing industry.

Recycled plastics reduce waste, conserve resources, and lower production costs. They also help decrease greenhouse gas emissions and support a circular economy. By using these materials, you contribute to a more sustainable manufacturing process.

Yes, recycled plastic can match virgin material quality when processed correctly. Advanced recycling techniques and quality control measures ensure consistent performance and durability in injection molding applications.

Industries like automotive, consumer goods, and packaging benefit significantly. They use recycled plastics to create eco-friendly products, reduce costs, and meet sustainability goals.

Recycled plastics may face challenges like material degradation and contamination. However, innovations in recycling technology and process optimization help overcome these issues, ensuring reliable performance.

Using recycled plastics lowers raw material costs and reduces energy consumption. Over time, these savings make manufacturing more cost-effective while supporting environmental sustainability.