Reducing lead times in plastic injection molding is critical for staying competitive. When you shorten lead times, you ensure faster production and meet tight production deadlines. However, achieving this isn't always easy. Manufacturers often face challenges like delays in material procurement and inefficient workflows. These issues can slow production speed and increase injection molding production costs. By focusing on precision tooling services and efficient production processes, you can create high-quality molds with enhanced part quality. Faster production not only improves efficiency but also ensures you deliver custom injection molds on time.

Inefficient workflows in mold design can significantly increase lead times. Poor scheduling and lack of coordination between teams often result in delays. For example, when multiple businesses handle different phases of the design process, visibility becomes limited. This makes planning difficult and reduces throughput. Additionally, frequent order changes or missed deadlines can disrupt manufacturing processes. These disruptions often escalate minor issues into major delays, affecting profitability and reputation.

| Aspect | Description |

|---|---|

| Scheduling | Challenges arise from multiple businesses working on different phases, leading to poor visibility and planning difficulties, which can result in missed opportunities and lower throughput. |

| Managing Changes | Manufacturing processes are often disrupted by order changes, missed deadlines, and communication failures, which can escalate small issues into significant delays affecting profitability and reputation. |

| Improving Performance | The lack of reliable data due to disjointed methods and manual processes hampers the ability to analyze performance, leading to inefficiencies and increased production delays. |

To overcome these challenges, you should streamline workflows and adopt digital tools for better collaboration. This ensures smoother transitions between design and production phases, reducing lead times.

Material procurement and supply chain disruptions are common bottlenecks in plastic injection molding. Sourcing high-quality raw materials can be challenging due to price fluctuations and unreliable suppliers. Transportation delays also impact the timely delivery of materials, increasing lead times. Poor inventory management further complicates the process, leading to either excess stock or shortages.

To address these issues, you should build strong relationships with reliable suppliers and invest in robust inventory management systems. This helps ensure a steady flow of materials and minimizes disruptions.

Communication gaps between design and production teams often lead to inefficiencies. When teams fail to share critical information, errors occur. These errors can delay production and increase costs. For instance, unclear design specifications may result in molds that do not meet requirements, requiring rework.

Statistical Process Control (SPC) can help identify and address these gaps. By inspecting random samples, you can detect variations in product quality and process parameters. SPC also allows you to analyze deviations that cause inefficiencies, ensuring smoother communication and better alignment between teams.

Encouraging regular meetings and using collaborative tools can bridge these gaps. This fosters better communication and ensures that both teams work toward the same goals, reducing lead times.

Relying on outdated manufacturing methods can significantly slow down your production process. Traditional techniques often lack the precision and speed required to meet modern demands. These methods may involve manual processes, older machinery, or inefficient workflows, all of which increase lead times and reduce overall efficiency.

Tip: Upgrading to modern manufacturing technologies can drastically improve your production speed and accuracy.

Here are some common issues caused by outdated methods:

To overcome these challenges, you should consider adopting advanced technologies. For example, upgrading to CNC machines or incorporating automation can streamline your operations. These tools offer greater precision and faster production times, helping you stay competitive.

| Outdated Methods | Modern Solutions |

|---|---|

| Manual processes | Automation and robotics |

| Aging equipment | CNC machining |

| Inefficient setups | Lean manufacturing |

Switching to modern methods may require an initial investment, but the long-term benefits outweigh the costs. You’ll experience faster lead times, improved product quality, and reduced operational expenses. By staying ahead of technological advancements, you ensure your business remains competitive in a fast-paced industry.

Note: Regularly evaluate your manufacturing processes to identify areas for improvement. Continuous upgrades will keep your operations efficient and future-ready.

Simplifying mold designs plays a crucial role in reducing lead times for custom injection molds. Complex designs often require additional machining, testing, and adjustments, which can slow down production. By focusing on simplicity, you can streamline the manufacturing process and improve production efficiency.

One effective approach is to collaborate with engineers and mold designers early in the design phase. This collaboration helps identify unnecessary features and ensures the design aligns with manufacturing capabilities. For example, engaging in Design for Manufacturability (DfM) discussions allows you to resolve potential moldability issues before they lead to costly rework. Additionally, optimizing the layout of mold cavities and cooling channels can significantly enhance efficiency by reducing cycle times.

Tip: Simplified designs not only save time but also reduce material waste, making the process more cost-effective and environmentally friendly.

By prioritizing simplicity, you can achieve faster production timelines while maintaining high-quality standards for your injection molds.

Choosing the right resin or material is critical for process optimization in injection molding. Different materials have unique properties that affect how quickly and efficiently they can be processed. For instance, some resins offer faster fill times, while others provide better thermal stability or mechanical strength.

| Resin Type | Mechanical Properties | Thermal Stability | Impact on Fill Times |

|---|---|---|---|

| ABS | High impact resistance | Moderate | Moderate |

| PEEK | High temperature capability | High | Low |

When selecting materials, you should evaluate factors like mechanical properties, chemical resistance, and thermal stability. Engineers often use quantitative analysis to determine how materials will perform under specific loads, stresses, and strains. Pre-approved and biocompatible materials can also streamline production by ensuring compliance with industry standards.

Note: The right material choice not only speeds up processing but also minimizes defects, reducing the need for rework and improving overall production efficiency.

By carefully selecting resins and materials, you can optimize injection mould tooling and achieve faster, more reliable results.

Simulation software has become an indispensable tool for refining mold designs and improving process optimization. These tools allow you to predict potential issues and make adjustments before production begins, saving time and resources. For example, software like SOLIDWORKS Plastics Standard provides insights into fill times and gate locations, while Moldex3D offers advanced features like 3D boundary-layer meshing for faster processing.

Using simulation software, you can evaluate critical factors such as mold temperature evolution, cooling uniformity, and cycle time efficiency. Features like freeze-time views help identify areas that may slow down cooling, enabling you to make targeted improvements. Early optimization of designs through simulation also reduces the likelihood of costly changes later in the process.

Callout: Simulation tools empower even junior designers to make informed decisions, ensuring better plastic parts and cost-efficient manufacturing.

By leveraging simulation software, you can refine your designs, enhance production efficiency, and reduce lead times for custom injection molds.

Involving engineers early in the design phase can significantly reduce lead times for custom plastic injection molds. Engineers bring valuable insights that help you identify potential issues before production begins. Their expertise ensures that your designs are practical, efficient, and aligned with manufacturing capabilities.

When you collaborate with engineers from the start, you create a foundation for success. Engineers can evaluate your design for manufacturability (DfM), ensuring it meets production requirements. This proactive approach minimizes the risk of costly rework and delays.

Tip: Early collaboration helps you avoid design flaws that could lead to production bottlenecks. It also ensures smoother transitions between design and manufacturing.

Note: Collaboration is a two-way street. Encourage your team to actively engage with engineers and value their input. This fosters a culture of teamwork and innovation.

Imagine you’re designing a mold for a complex part with intricate details. Without early input from engineers, you might overlook critical factors like cooling channel placement or gate location. These oversights could lead to defects, longer cycle times, and increased costs. By involving engineers early, you can address these challenges upfront, ensuring a smoother production process.

Additive manufacturing, commonly known as 3D printing, has revolutionized rapid prototyping in injection molding. This technology eliminates the need for upfront tooling costs, making it a cost-effective solution for creating prototypes. You can quickly produce complex geometries and multiple iterations without the delays associated with traditional methods.

One of the key advantages of additive manufacturing is its speed. With 3D printing, you can start prototype development almost immediately. This rapid turnaround allows you to test designs, identify flaws, and make adjustments faster than ever before. The flexibility in design also ensures that even intricate parts can be produced with ease.

By leveraging additive manufacturing, you can streamline the prototyping phase, saving both time and resources while ensuring high-quality results.

Automation plays a critical role in improving efficiency and reducing lead times in injection molding. Automated systems maintain continuous operations, minimizing interruptions and ensuring consistent production quality. For example, robotic automation can handle repetitive tasks like material handling, mold loading, and part removal, freeing up your workforce for more complex activities.

Statistics show that automation can boost productivity by 20% to 25% in manufacturing sectors. Companies that adopt robotic automation often experience a 30% increase in production efficiency. These improvements translate to shorter lead times and higher output.

| Improvement | Description | Impact on Lead Time |

|---|---|---|

| Quick-change mold systems | Enables faster mold changes, minimizing downtime. | Reduces lead times by up to 50%. |

| Automated production lines | Maintains continuous operations, reducing interruptions. | Significant reduction in lead times. |

| Efficient thermal management | Improves cycle speed and reduces cooling times. | Enhances overall production efficiency. |

Tip: Investing in automation not only reduces lead times but also enhances product consistency and quality.

By integrating automation into your processes, you can achieve faster production cycles, lower operational costs, and a competitive edge in the market.

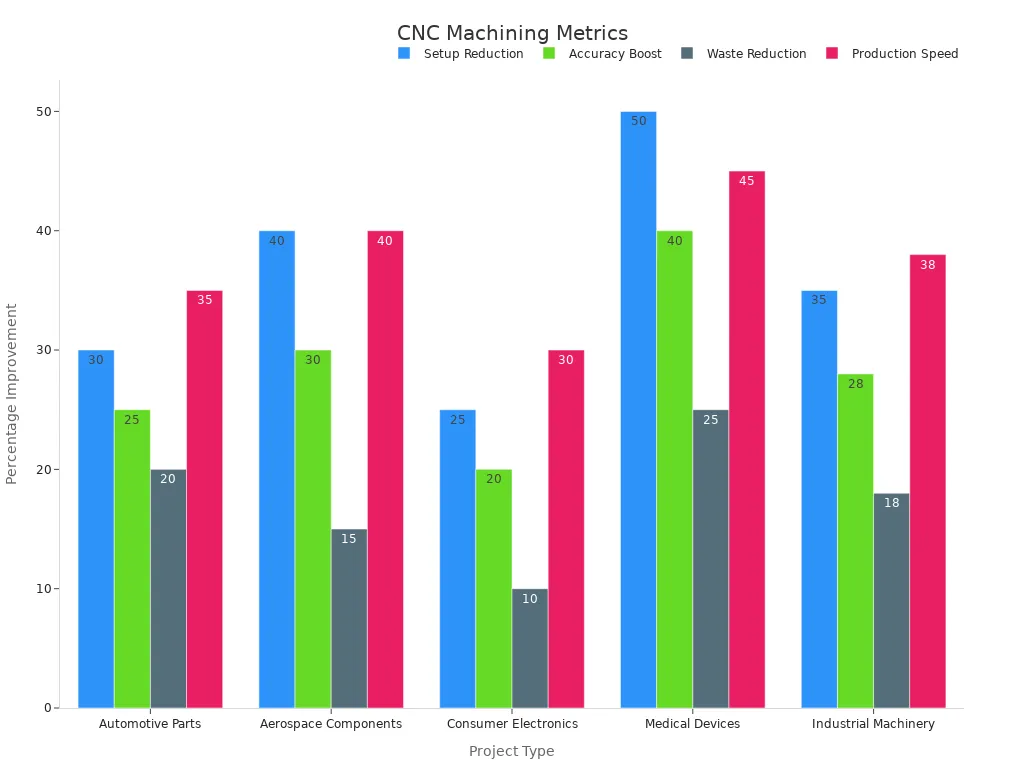

CNC machining has become a cornerstone of modern injection molding due to its precision and speed. Advanced CNC techniques, such as multi-axis and high-speed machining, allow you to produce complex parts with tight tolerances. These capabilities significantly reduce production times and improve overall efficiency.

For example, CNC machining can reduce setup times by up to 50% for medical devices and improve production speed by 40% for aerospace components. The precision of CNC machines also minimizes material waste, making the process more cost-effective.

| Project Type | Reduction in Setup Time | Improvement in Accuracy | Reduction in Waste | Speed of Production |

|---|---|---|---|---|

| Automotive Parts | 30% | 25% | 20% | 35% |

| Aerospace Components | 40% | 30% | 15% | 40% |

| Consumer Electronics | 25% | 20% | 10% | 30% |

| Medical Devices | 50% | 40% | 25% | 45% |

| Industrial Machinery | 35% | 28% | 18% | 38% |

Note: Regularly upgrading your CNC equipment ensures you stay ahead of industry standards and maintain optimal production efficiency.

By adopting CNC machining, you can enhance precision, reduce waste, and achieve faster production times, making it an essential technology for modern injection molding.

Hybrid manufacturing combines traditional and advanced methods to create complex molds with greater efficiency. By integrating techniques like additive manufacturing and CNC machining, you can achieve faster production times and higher precision. This approach is especially useful for molds with intricate designs or challenging geometries.

Hybrid manufacturing offers several advantages that directly impact lead times and production quality. Here’s how it helps:

Tip: Using hybrid manufacturing allows you to tackle complex projects without compromising on speed or quality.

The measurable benefits of hybrid manufacturing make it a game-changer for mold production. Here’s a breakdown of the key outcomes:

| Measurable Outcome | Description |

|---|---|

| Reduced Lead Times | Hybrid techniques can cut lead times by up to 50%. |

| Enhanced Design Accuracy | Improved precision in mold design through advanced techniques. |

| Improved Material Efficiency | More efficient use of materials in the production process. |

These outcomes highlight why hybrid manufacturing is essential for reducing lead times and improving overall efficiency.

Hybrid manufacturing is ideal for industries requiring high precision and complex designs. For example, automotive and aerospace sectors often use these techniques to produce molds for intricate components. You can also apply hybrid methods to medical devices, where accuracy and reliability are critical.

To adopt hybrid manufacturing, start by evaluating your current processes. Identify areas where advanced techniques like 3D printing or CNC machining can complement traditional methods. Invest in equipment that supports hybrid workflows, such as multi-axis CNC machines or industrial-grade 3D printers. Training your team to use these technologies effectively ensures you maximize their potential.

Note: Regularly assess your production outcomes to refine your hybrid approach. Continuous improvement keeps your operations efficient and competitive.

By leveraging hybrid manufacturing techniques, you can produce complex molds faster and with greater precision. This approach not only reduces lead times but also enhances the quality and reliability of your molds.

Maintaining in-house tooling facilities offers several benefits that can significantly improve your production process. One major advantage is the ability to minimize downtime. When you manage tooling internally, you can quickly disassemble molds, identify issues, and reassemble them efficiently. This reduces delays during mold transfers and keeps your production on schedule.

Another benefit is improved efficiency. Standardized procedures and clear installation directions streamline operations, leading to faster cycle times and reduced scrap rates. Additionally, in-house tooling enhances product quality by preventing defects like flash and warpage. Proper maintenance ensures molds perform optimally, resulting in higher-quality products.

| Improvement Type | Description |

|---|---|

| Minimized Downtime | A thorough system for disassembling molds can speed up identification and reassembly, reducing downtime during transfers. |

| Improved Efficiency | Streamlined installation with clear directions and standardized procedures enhances operational efficiency. |

| Enhanced Quality | Proper maintenance leads to higher quality products by preventing defects, thus improving overall production quality. |

By investing in in-house tooling facilities, you gain better control over your processes, reduce costs, and improve overall efficiency.

Skilled operators are essential for maximizing the potential of advanced machinery. Training your team ensures they can handle complex equipment and maintain high production standards. Well-trained operators can identify issues early, reducing the risk of costly errors and downtime.

You should provide hands-on training sessions and encourage continuous learning. For example, workshops on CNC machining or automation systems can help your team stay updated on the latest technologies. Skilled operators also improve efficiency by optimizing machine settings and minimizing material waste. This not only enhances productivity but also reduces operational costs.

Tip: Investing in operator training pays off in the long run by improving production quality and reducing lead times.

Preventive maintenance is crucial for keeping your tools and equipment in top condition. Regular maintenance reduces the likelihood of unexpected breakdowns, ensuring your machines run smoothly. This approach also lowers repair costs and minimizes the need for large-scale repairs.

A structured preventive maintenance program can significantly enhance operational efficiency. For instance, scheduling routine inspections helps you identify wear and tear before it leads to equipment failure. This proactive approach increases machine reliability and boosts overall production output.

By prioritizing preventive maintenance, you can avoid costly disruptions and maintain a consistent production flow. This ensures your tools and equipment deliver optimal performance over time.

Streamlining workflows is essential for minimizing production downtime and improving efficiency. When you optimize workflows, you eliminate unnecessary steps and ensure every process runs smoothly. This approach reduces delays and helps you maintain consistent production output.

One effective way to streamline workflows is by standardizing procedures. Clear and consistent guidelines ensure that every team member knows their responsibilities. For example, creating step-by-step instructions for mold setup and maintenance can prevent errors and save time. Standardization also makes it easier to train new employees, further enhancing productivity.

Another strategy involves using digital tools to monitor and manage workflows. Workflow management software allows you to track progress in real time. These tools help you identify bottlenecks and address them before they cause significant delays. For instance, if a particular task takes longer than expected, you can reallocate resources to keep the process on track.

The benefits of streamlined workflows are measurable. Studies show that optimizing workflows can increase throughput by 15% to 35% and improve ROI by 25% to over 50%.

| Metric | Value Range |

|---|---|

| Throughput Increase (%) | 15% to 35% |

| ROI Improvement (%) | 25% to over 50% |

By implementing these strategies, you can achieve reduced downtime and enhance overall efficiency. This not only saves time but also boosts profitability, ensuring your operations remain competitive.

Tip: Regularly review your workflows to identify areas for improvement. Continuous optimization ensures your processes stay efficient and adaptable to changing demands.

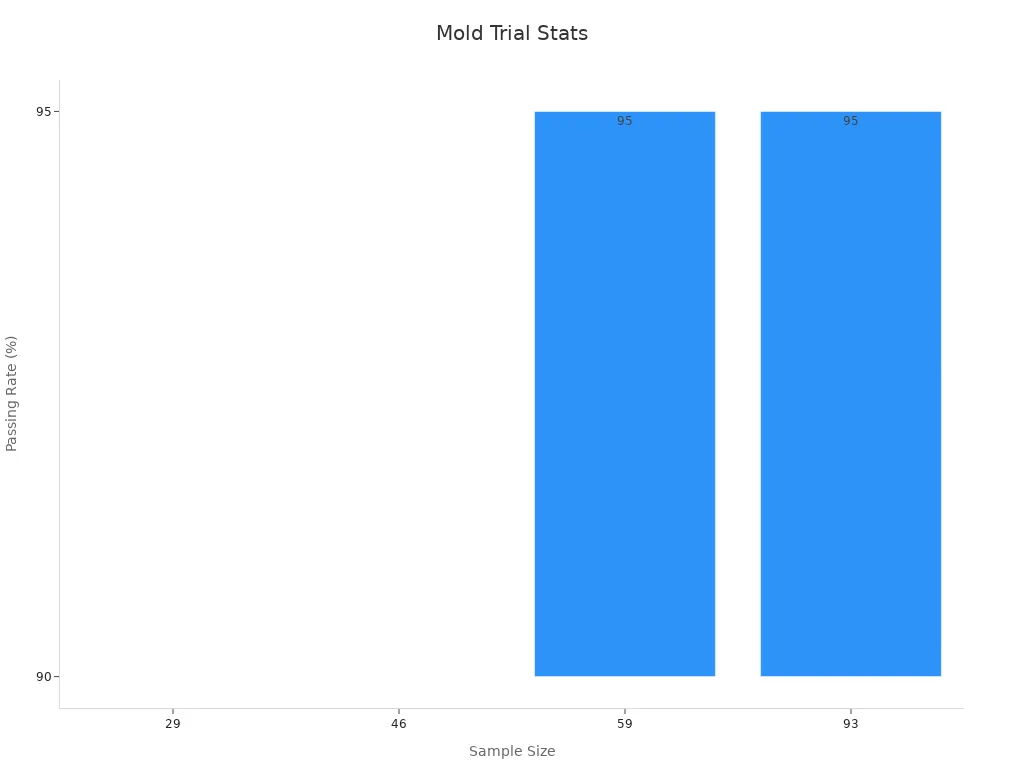

Mold trials are essential for identifying potential issues before full-scale production begins. By testing injection molds early, you can detect defects such as warping, uneven cooling, or improper gate placement. Addressing these problems upfront saves time and reduces costly rework later in the process.

Statistical data highlights the importance of early defect detection during mold trials. For instance, a study showed that increasing the sample size during trials improves the passing rate and lowers the risk of failures. The table below illustrates this relationship:

| Sample Size | Confidence Level | Passing Rate | Risk Level |

|---|---|---|---|

| 29 | 95% | 90% | Lower |

| 59 | 95% | 95% | Higher |

| 46 | 95% | 90% | With 1 Failure |

| 93 | 95% | 95% | With 1 Failure |

By conducting thorough mold trials, you ensure your injection molds meet quality standards and perform efficiently during production.

Quality control systems play a vital role in maintaining high standards and reducing rework. Without effective quality control, factories face higher scrap rates and increased labor costs, which disrupt production schedules. Implementing advanced systems ensures consistent quality and minimizes waste.

Modern quality control systems use AI and predictive analytics to optimize processes. These systems detect defects early, saving time and resources. They also improve overall equipment effectiveness (OEE), ensuring peak productivity. Key benefits include:

- Reduced rework through early defect detection.

- Lower material and labor costs.

- Enhanced production efficiency with optimized resource allocation.

By integrating quality control systems, you can maintain consistent standards and improve the reliability of your injection molds.

Feedback loops are critical for continuous improvement in manufacturing. By analyzing data from mold trials and production runs, you can identify areas for enhancement. For example, feedback from operators and quality control teams helps refine mold designs and optimize workflows.

To create effective feedback loops:

1. Collect data from mold trials and quality inspections.

2. Analyze the data to identify recurring issues.

3. Implement changes based on findings.

4. Monitor the results to ensure improvements are effective.

This iterative process ensures your injection molds perform at their best, reducing lead times and enhancing overall quality.

Rework can significantly increase production costs and delay project timelines. Detecting defects early in the injection molding process helps you avoid these setbacks. By identifying issues before full-scale production, you can save time, reduce waste, and improve overall efficiency.

Use Advanced Inspection Tools

Tools like ultrasonic testing and thermal imaging can help you spot defects such as voids, cracks, or uneven cooling. These technologies provide real-time feedback, allowing you to address problems immediately.

Conduct Regular Mold Trials

Running mold trials before mass production helps you identify potential issues. For example, you can test for proper gate placement, cooling uniformity, and material flow. This ensures the mold performs as expected.

Implement Statistical Process Control (SPC)

SPC involves monitoring production data to detect variations in quality. By analyzing trends, you can predict and prevent defects before they occur.

Tip: Always document findings from mold trials and inspections. This creates a reference for future projects and helps you refine your processes.

| Benefit | Description |

|---|---|

| Reduced Rework | Fixing defects early minimizes the need for costly corrections. |

| Improved Product Quality | Early detection ensures molds meet design specifications. |

| Lower Material Waste | Identifying issues upfront prevents unnecessary material consumption. |

| Faster Production | Resolving defects early keeps your production schedule on track. |

By prioritizing early defect detection, you can streamline your operations and deliver high-quality molds on time. This proactive approach not only saves resources but also enhances customer satisfaction.

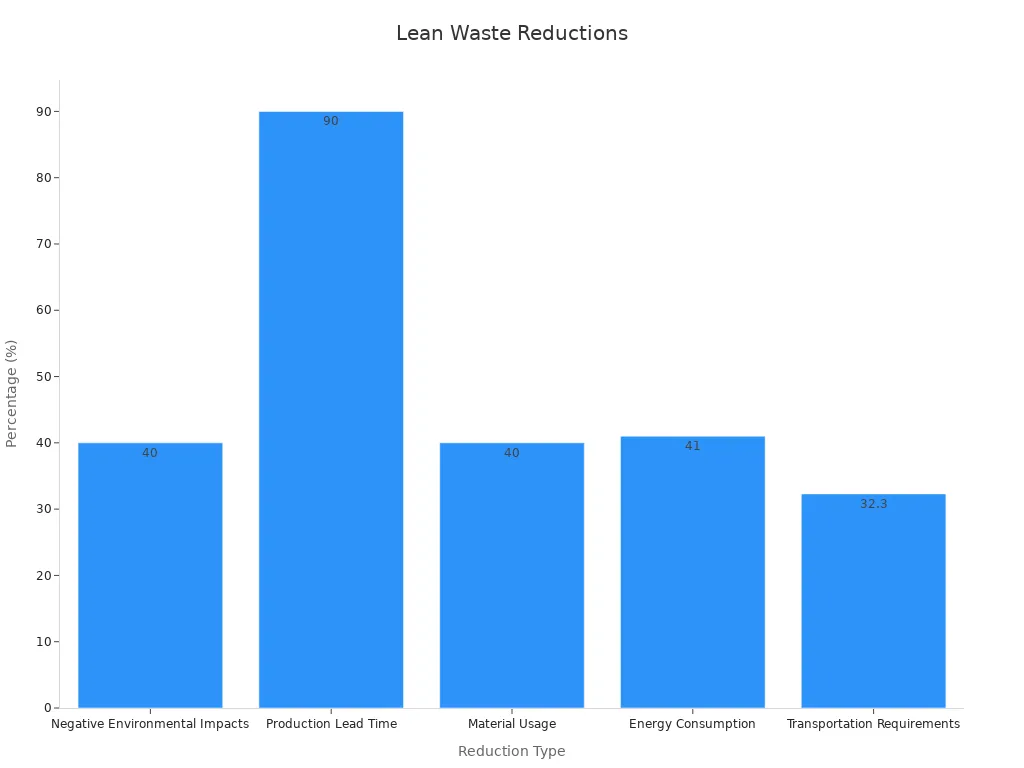

Lean manufacturing focuses on reducing waste to improve efficiency and quality in injection molds. Waste can take many forms, such as excess material usage, unnecessary energy consumption, or inefficient workflows. By identifying and eliminating these inefficiencies, you can significantly reduce lead times and enhance overall production quality.

For example, lean practices have shown measurable reductions in waste across various areas of injection molding. The table below highlights some of these improvements:

| Reduction Type | Percentage Reduction |

|---|---|

| Negative Environmental Impacts | 40% |

| Production Lead Time | 90% |

| Material Usage | 40% |

| Energy Consumption | 41% |

| Transportation Requirements | 32.3% |

By adopting lean principles, you can achieve these reductions while maintaining high-quality standards. Streamlining processes and minimizing waste not only saves resources but also ensures your injection molds meet production deadlines.

Efficient workflows are essential for reducing cycle times in injection molding. When you optimize each step of the process, you eliminate unnecessary delays and improve overall efficiency. For instance, standardizing procedures for mold setup and maintenance ensures that every task is completed quickly and accurately.

You can also use digital tools to monitor workflows in real time. These tools help you identify bottlenecks and make adjustments to keep production on track. For example, if a particular stage takes longer than expected, reallocating resources can prevent delays. Shorter cycle times mean faster lead times, allowing you to meet customer demands more effectively.

Tip: Regularly review your workflows to identify areas for improvement. Continuous optimization ensures your processes remain efficient and adaptable.

Continuous improvement is a core principle of lean manufacturing. By regularly evaluating your processes, you can identify opportunities to enhance efficiency and reduce lead times. This approach involves small, incremental changes that add up to significant improvements over time.

One effective strategy is to create feedback loops. Collect data from mold trials and production runs to pinpoint recurring issues. Use this information to refine your workflows and improve quality. For example, if you notice frequent defects in a specific mold design, adjusting the design early can prevent rework and save time.

Callout: Continuous improvement not only reduces lead times but also enhances product quality and customer satisfaction.

By committing to ongoing improvements, you ensure your injection molds remain competitive in a fast-paced industry. This proactive approach helps you stay ahead of challenges and maintain high standards of efficiency and quality.

Efficient supply chain management ensures timely material delivery, which directly impacts lead times in injection molding. Delays in material procurement can disrupt production schedules and increase costs. By optimizing your supply chain, you can maintain a steady flow of materials and keep your operations running smoothly.

Start by tracking key performance metrics. Monitoring the on-time delivery rate helps you evaluate supplier reliability. A high rate indicates that your suppliers consistently meet deadlines. Additionally, tracking overall equipment effectiveness (OEE) ensures that your machines operate efficiently without delays caused by material shortages. Measuring cycle time also provides insights into how quickly your production processes run.

Tip: Use these metrics to identify bottlenecks and address them before they escalate into larger issues.

Building strong relationships with reliable suppliers is another critical step. Reliable suppliers reduce the risk of disruptions caused by late deliveries or inconsistent material quality. You should also diversify your supplier base to avoid over-reliance on a single source. This strategy minimizes risks during unexpected events like supply chain disruptions or staff shortages.

Implementing inventory management systems further enhances supply chain efficiency. These systems help you maintain optimal stock levels, preventing both overstocking and shortages. For example, automated tools can alert you when inventory reaches a critical level, ensuring timely reordering. This reduces machine downtime and keeps production schedules on track.

By focusing on these strategies, you can streamline your supply chain and ensure timely material delivery. This not only reduces lead times but also enhances overall production efficiency.

Reducing lead times for custom injection molds offers significant advantages. By streamlining workflows, adopting advanced technologies, and applying lean manufacturing principles, you can achieve faster production cycles and higher efficiency. These strategies not only save costs through improved manufacturing processes but also enhance customer satisfaction by delivering quality products on time.

Adopting these practices ensures your operations remain competitive while meeting the growing demands of the industry.

Streamline your workflows and adopt advanced technologies like CNC machining or automation. These methods improve efficiency and reduce delays. Early collaboration with engineers also helps identify potential issues, saving time during production.

Simulation software predicts potential issues in mold designs. It allows you to test factors like cooling uniformity and material flow before production. This reduces errors and ensures faster, more efficient manufacturing.

The right material speeds up processing and minimizes defects. For example, resins with faster fill times reduce cycle durations. Proper material selection also ensures compliance with industry standards, avoiding delays caused by rework.

Preventive maintenance keeps tools and equipment in optimal condition. Regular inspections reduce unexpected breakdowns and extend machine lifespan. This ensures consistent production flow and minimizes downtime.

Lean manufacturing eliminates waste and improves efficiency. It reduces material usage, energy consumption, and cycle times. By optimizing workflows, you achieve faster production and lower costs while maintaining high-quality standards.