Liquid silicone rubber is a versatile material known for its exceptional durability, flexibility, and safety. It offers tensile strength ranging from 400 to 1520 psi, making it highly resistant to wear and tear. This material also boasts superior elasticity, which ensures long-lasting performance in various applications. For household products, liquid silicone rubber stands out as a safer alternative due to its non-toxic nature and resistance to extreme temperatures.

Its growing popularity is evident in the numbers. The global market for liquid silicone rubber was valued at $2.27 billion in 2019 and is projected to reach $4.06 billion by 2027, growing at a rate of 7.1%. This rapid growth reflects its increasing use in everyday items that prioritize safety, durability, and functionality.

Liquid silicone rubber (LSR) is a high-performance elastomer that combines flexibility, durability, and safety. Unlike traditional rubbers, LSR is a two-part platinum-cured silicone that starts as a liquid and cures into a solid form. This unique composition allows it to be molded into intricate shapes with precision. Its versatility makes it suitable for a wide range of applications, from medical devices to household products.

LSR has been used in biomedical applications since the 1940s, including artificial heart valves and breast implants. Its hydrophobic properties and biocompatibility make it ideal for drug delivery systems and long-term implanted devices like pacemakers. These characteristics highlight its adaptability and reliability in demanding environments.

LSR stands out due to its exceptional properties, which make it a preferred material for various industries. Here’s a detailed look at its key characteristics:

| Property/Characteristic | Description |

|---|---|

| High-Temperature Resistance | Withstands constant temperatures up to 600°F (316°C) and intermittent temperatures of 700°F (371°C). |

| Low-Temperature Flexibility | Remains flexible even at temperatures well below 0°F. |

| Biocompatibility | Approved for medical applications, including skin contact and implantable uses. |

| Chemical Resistance | Resists thermal, electrical, and chemical degradation, though susceptible to certain solvents. |

| Compression Set | Maintains shape and elasticity after repeated compression. |

| Shear Thinning | Exhibits reduced viscosity under shear stress, aiding in precise molding. |

Additionally, LSR is highly resistant to wear, tear, and UV radiation. Its flexibility makes it ideal for products requiring elastic properties, such as seals and gaskets. These features ensure long-lasting performance and reliability in various applications.

Liquid silicone rubber has revolutionized the way you think about household products. Its unique combination of properties ensures safety, durability, and functionality. For example, LSR’s non-toxic nature makes it perfect for kitchenware and baby care items. It can withstand extreme temperatures, ensuring that products like oven mitts and baking molds remain safe and effective.

The LSR 2025 conference highlighted its superior heat resistance, low-temperature flexibility, and excellent electrical insulation properties. These attributes make it ideal for complex and precision parts in high-performance industries. In household applications, these same qualities translate to better performance and longer-lasting products.

Moreover, LSR’s ability to maintain structural integrity in harsh environments ensures reliability. Whether it’s a gasket in a washing machine or a seal in a coffee maker, LSR delivers consistent results. Its versatility in design allows manufacturers to create innovative products that meet your needs while maintaining high standards of safety and quality.

When it comes to household products, durability is a top priority. Liquid silicone rubber excels in this area due to its exceptional resistance to wear and tear. Unlike traditional materials, it maintains its structural integrity even under constant use. For example, seals and gaskets made from this material can endure repeated compression without losing their shape. This property, known as compression set resistance, ensures that your household items remain functional for years.

Additionally, liquid silicone rubber resists environmental factors like UV radiation and extreme temperatures. Whether exposed to freezing conditions or intense heat, it retains its flexibility and strength. This makes it ideal for outdoor applications, such as weatherproof seals for windows and doors. Its tear strength further enhances its durability, ensuring that products made from LSR material can withstand high-stress environments without breaking or degrading.

Safety is another critical factor in household products, especially those that come into contact with food or skin. Liquid silicone rubber is non-toxic and hypoallergenic, making it one of the safest materials available. It resists mold and bacteria growth, ensuring that your kitchenware and baby care items remain hygienic. Regulatory bodies like the FDA and ISO have certified LSR for use in food-grade and medical applications, confirming its safety and purity.

Here are some key safety features of liquid silicone rubber:

- It is biocompatible, meaning it is safe for skin contact and even implantable medical devices.

- It meets stringent standards, including FDA, UPS, ISO, and CFR certifications.

- It is formulated to be safer than other silicone variants, such as solid silicone rubber and HTV.

These qualities make LSR material an excellent choice for products like baby bottle nipples, pacifiers, and baking molds. You can trust that items made from this material are free from harmful chemicals and safe for your family.

Liquid silicone rubber stands out for its versatility in design and functionality. Its unique properties allow manufacturers to create products with complex geometries and intricate details. This is possible because of its low viscosity and shear-thinning behavior, which enable precise molding through liquid injection processes. As a result, you get products that are not only functional but also aesthetically pleasing.

The material's performance metrics further highlight its adaptability:

- Tensile Modulus: Ensures structural integrity, crucial for durable household items.

- Elongation: Allows the material to stretch without breaking, ideal for flexible products like seals and gaskets.

- Tear Strength: Enhances durability, especially in high-stress applications.

- Durometer: Determines hardness, influencing the feel and usability of items like kitchen utensils.

- Density: Affects the weight and comfort of the final product, ensuring ease of use.

These properties make liquid silicone rubber suitable for a wide range of household applications. From heat-resistant oven mitts to flexible ice cube trays, the possibilities are endless. Its ability to combine functionality with innovative design ensures that your household products not only perform well but also look great.

Liquid silicone rubber molding is a specialized injection molding process designed for high-volume production of durable and precise silicone products. This process transforms liquid silicone rubber into solid, functional components through a series of carefully controlled steps.

Here’s how the process works:

1. Create LSR Molding Tool: A CNC-machined mold is fabricated to withstand high temperatures and ensure precision.

2. Prepare Material: Liquid silicone rubber is mixed with a catalyst in a 1:1 ratio using a pumping system.

3. Inject the Material into Mold: The mixture is heated and injected into the mold cavity under high pressure.

4. Curing Process: The mold is heated to cure the silicone into its final solid form.

5. Cooling and Demolding: Products are cooled and removed from the mold, often using automated systems.

6. Post-molding Secondary Operations: Additional processes like slitting, printing, or assembly are performed to finalize the product.

This injection molding process ensures consistent quality and efficiency, making it ideal for high-volume production of household items like seals, gaskets, and kitchenware.

The liquid silicone rubber molding process excels in precision and efficiency, ensuring that every product meets exact specifications. Manufacturers follow strict quality control standards, such as ISO 9001:2015, to evaluate and inspect each stage of production.

| Stage | Description |

|---|---|

| Evaluation & Quality Control | Ensures product output meets specifications through document control, inventory management, and inspection protocols. |

| Prototyping | Creates samples to test performance before full-scale production, minimizing errors and waste. |

| LSR Inspection & Testing | Verifies tensile properties and quality using ASTM D412 standards. |

| Full-Scale Production | Requires specialized expertise in liquid silicone rubber molding, addressing unique challenges compared to thermoplastics. |

| Materials Selection | Focuses on selecting advanced LSR formulations for improved product properties. |

| Gating and Venting | Designs gates and vents to optimize part quality and reduce defects. |

| Expected Tolerances | Specifies linear tolerances and flash allowances for precise part design. |

| Part Ejection | Uses tailored ejection methods to ensure smooth removal of molded parts. |

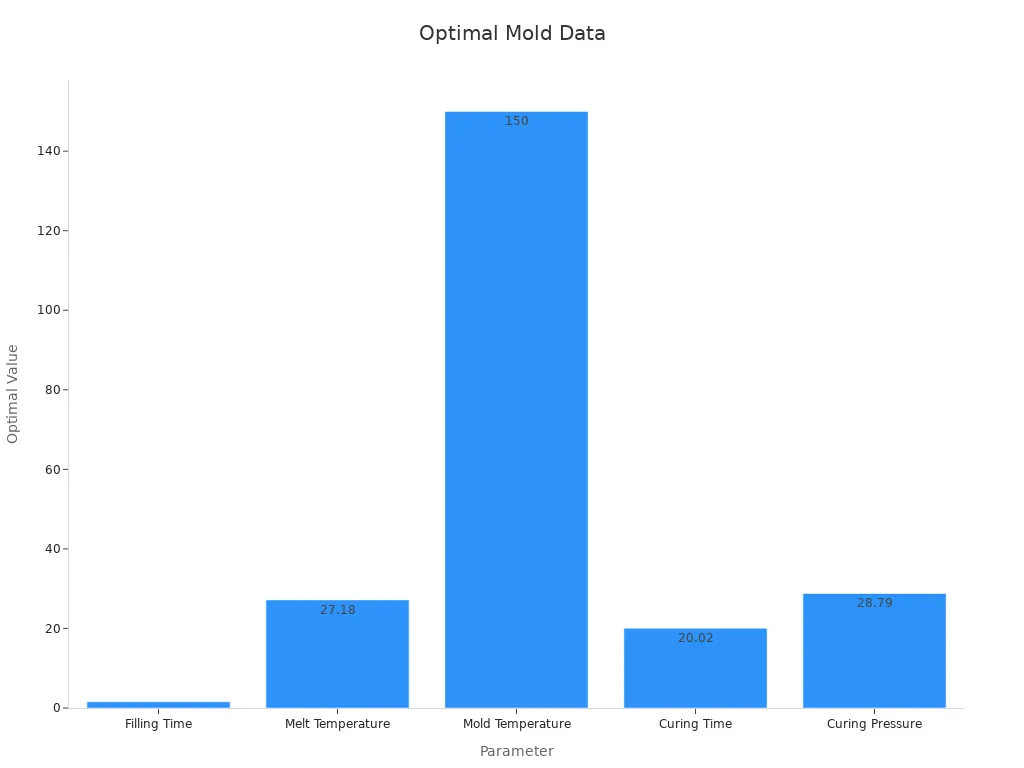

Recent studies highlight quantifiable improvements in production precision. For example, optimal mold parameters include a filling time of 1.57 seconds, a curing time of 20.02 seconds, and a curing pressure of 28.79 MPa. These advancements reduce residual stress and volume shrinkage, ensuring high-quality output.

Liquid silicone rubber molding offers significant ecological benefits. The process uses sustainable materials and aligns with circular economy initiatives. Manufacturers are developing recyclable and bio-based LSR formulations to reduce environmental impact.

Key environmental advantages include:

- Lower waste generation during production.

- Enhanced energy efficiency due to advanced molding techniques.

- Reduced reliance on non-renewable resources.

These innovations reflect the industry’s commitment to sustainability while maintaining the versatility and durability of silicone rubber. By choosing products made through this process, you contribute to a greener future without compromising quality.

Liquid silicone rubber has become a popular choice for kitchenware and food-grade utensils due to its durability and safety. You’ll find it in products like cooking utensils, oven mitts, baking cups, and ice cube molds. These items benefit from LSR’s ability to withstand extreme temperatures, ensuring they remain functional whether you’re baking or freezing.

| Application Area | Examples of Products | Benefits |

|---|---|---|

| Kitchenware | Cooking utensils, oven mitts, baking cups, ice cube molds | Durable, withstands extreme temperatures |

| Food Storage | Baby bottles, pacifiers, food storage products | Safe, strong, FDA-approved materials |

| Industrial Use | Valves, membranes, gaskets | Easy to sterilize, low creep and compression set |

LSR’s non-toxic and FDA-approved nature ensures that your kitchen tools are safe for cooking and storing food. Its resistance to bacteria and mold growth further enhances hygiene, making it a reliable material for everyday use.

When it comes to baby care products, safety and performance are non-negotiable. Liquid silicone rubber meets these demands with its hypoallergenic and non-toxic properties. You’ll see it in baby bottle nipples, pacifiers, and teething toys. These products are not only safe but also durable, ensuring they can withstand the wear and tear of daily use.

| Feature | Details |

|---|---|

| Temperature Range | -55 °C to +210 °C |

| Food-Contact Compliance | Suitable for food contact applications under BfR and FDA regulations |

| Volatile Content | Reduced volatile content |

LSR’s ability to endure a wide temperature range ensures that baby products remain safe whether you’re sterilizing them in boiling water or storing them in the freezer. Its reduced volatile content and compliance with food-contact regulations make it a trusted choice for parents.

Seals and gaskets made from liquid silicone rubber offer unmatched durability and flexibility. These components are essential in household appliances like dishwashers, washing machines, and faucets. LSR’s resistance to extreme temperatures and environmental elements ensures long-lasting performance.

Whether you need a gasket for a coffee maker or a seal for a window, LSR delivers consistent results. Its excellent mechanical properties, including elongation and tear strength, ensure that these components perform reliably under stress.

Liquid silicone rubber (LSR) offers several advantages over plastics, especially for household products. Its superior chemical resistance makes it ideal for items that require frequent cleaning with harsh agents. Unlike many plastics, LSR remains UV-stable, allowing it to endure outdoor conditions for decades without cracking or fading.

LSR also outperforms thermoplastic elastomers (TPE) in temperature resistance. It maintains its properties across a wide range, from -60°C to 250°C, making it suitable for both freezing and high-heat applications. Additionally, its low viscosity and ease of processing allow for intricate designs, enabling manufacturers to create complex and functional household items.

| Performance Metric | Liquid Silicone Rubber (LSR) | Plastics |

|---|---|---|

| Compression Set Resistance | Excellent across -60°C to 250°C | Varies significantly |

| Elongation | High, suitable for stretching | Lower, less flexible |

| Temperature Range | -60°C to +250°C | Limited range |

| Biocompatibility | High, suitable for medical use | Varies |

When compared to natural rubber, LSR stands out for its durability and reliability. It can last for decades under normal conditions, far exceeding the lifespan of natural rubber. This longevity makes it a cost-effective choice for household products.

LSR also resists heat, UV light, and chemicals better than natural rubber. These properties make it ideal for outdoor applications like weatherproof seals and gaskets. Its performance shines in demanding environments, such as outdoor electrical insulation and medical equipment, where reliability is critical.

Although LSR may have a higher upfront cost than some materials, its long-term value is unmatched. Its durability reduces the need for frequent replacements, saving you money over time. Products made from LSR maintain their performance even after years of use, ensuring reliability and peace of mind.

Additionally, LSR’s versatility in design and functionality allows manufacturers to create innovative products that meet your needs. Its ability to combine durability, safety, and performance makes it a smart investment for household solutions.

Liquid silicone rubber offers unmatched benefits for household products. Its ability to withstand extreme temperatures, resist chemicals, and maintain flexibility ensures durability and safety. The material’s biocompatibility makes it ideal for food-related items like cooking tools and storage containers.

| Property/Benefit | Description |

|---|---|

| Temperature Resistance | Can withstand extreme temperatures from −55 to 300 °C (−70 to 570 °F). |

| Chemical Stability | Non-reactive and stable, suitable for various household applications. |

| Biocompatibility | Safe for use in food-related products like cooking and storage items. |

| Flexibility | Offers durability and adaptability for various household items. |

| Applications | Used in cooking, baking, food storage, and more household products. |

Explore LSR-based solutions to enhance your home with products that combine innovation, safety, and long-term value.

Liquid silicone rubber is non-toxic and hypoallergenic. It resists bacteria and mold growth, making it ideal for food-grade and baby products. Regulatory approvals, such as FDA and ISO certifications, confirm its safety for household and medical applications.

Yes, liquid silicone rubber can be recycled. Manufacturers are developing bio-based formulations to reduce waste. This aligns with sustainability goals in industries like the medical device industry and household product manufacturing.

Liquid silicone rubber withstands temperatures from -60°C to 250°C. It remains flexible in freezing conditions and stable under high heat. This makes it suitable for kitchenware, seals, and even components in the medical device industry.

Yes, liquid silicone rubber resists UV radiation, water, and environmental factors. It maintains its properties over time, making it perfect for outdoor seals, gaskets, and other durable components.

Its biocompatibility, durability, and resistance to chemicals make it ideal for medical applications. Liquid silicone rubber is used in devices like pacemakers and seals, ensuring safety and reliability in critical environments.