Selecting the best plastic injection molding service for automotive parts manufacturing can directly impact the quality and reliability of your products. The global market for injection-molded automotive parts continues to grow, driven by advancements in electric vehicles and eco-friendly materials. A custom injection molding manufacturer with experience and certifications ensures efficient production while meeting environmental standards. Rigorous quality control processes and compliance with certifications like ISO 9001 are essential. By prioritizing these factors, you can find the right one to streamline the injection molding process and achieve consistent results.

Defining product specifications is the first step in selecting the right custom injection molding manufacturer. Automotive parts require precision and durability to meet industry standards. Certifications like IATF 16949 and ISO 9001 ensure that the manufacturer adheres to strict quality and safety requirements. For environmentally conscious projects, ISO 14001 certification highlights a commitment to sustainable practices.

| Standard | Description |

|---|---|

| IATF 16949 | Ensures safe and reliable automotive products that meet regulatory demands. |

| ISO 9001 | Improves customer satisfaction and operational efficiency. |

| ISO 14001 | Focuses on reducing environmental impact. |

| ISO 45001 | Promotes workplace health and safety. |

When defining specifications, consider the type of plastic resin and its suitability for the product’s end use. For example, high-performance resins may be necessary for parts exposed to extreme temperatures or stress. A clear design concept ensures the manufacturer understands your vision and delivers parts that meet functional requirements.

Production volume plays a critical role in custom injection molding. Large-scale projects benefit from economies of scale, reducing the cost per part as production increases. Custom injection molded parts offer precision and consistency, ensuring every piece meets exact specifications. Material versatility is another advantage, allowing you to select the best resin for durability and performance.

Collaborate with the manufacturer to determine the optimal material for your automotive parts. For example, lightweight plastics may improve fuel efficiency, while reinforced materials enhance strength.

A well-defined design ensures your custom injection molded parts meet both aesthetic and functional requirements. Performance, reliability, and production efficiency are key factors to consider. For automotive components, material selection directly impacts durability and functionality. Injection molding settings also influence the precision and quality of the final product.

| Key Factors | Implications for Design and Functionality |

|---|---|

| Performance | Ensures parts meet operational requirements. |

| Production Efficiency | Optimizes the manufacturing process. |

| Reliability | Guarantees parts withstand environmental conditions. |

| Material Selection | Enhances durability and performance. |

| Injection Molding Settings | Improves precision and quality. |

Collaborate with the manufacturer to refine your design concept. For example, if your parts require intricate details, advanced injection molding technology ensures accuracy. By clearly communicating your functional needs, you can achieve parts that align with your automotive project goals.

When evaluating an automotive molding company, you should prioritize its experience in producing high-quality plastic car parts. Manufacturers with extensive experience understand the unique challenges of automotive plastic injection molding, such as meeting durability requirements and ensuring precision in complex designs. Experienced manufacturers also excel in material selection, helping you choose resins that enhance performance and reduce costs.

| Evaluation Criteria | Importance |

|---|---|

| Certification (IAT16949:2016) | Indicates commitment to quality and adherence to automotive industry standards. |

| Experience in Automotive Parts Manufacture | Essential for understanding part performance, quality, and specific material requirements. |

| Design for Manufacturability Studies | Helps in identifying design flaws early, saving time and costs in production. |

| Specialization in Metal-to-Plastic Conversion | Reduces vehicle weight and costs, showcasing innovation in manufacturing processes. |

Collaborating with a plastic car parts manufacturer that specializes in automotive projects ensures your parts meet industry benchmarks. For example, manufacturers with expertise in metal-to-plastic conversion can help reduce vehicle weight, improving fuel efficiency and lowering production costs.

Certifications are a reliable indicator of a manufacturer’s reputation and commitment to quality. You should look for certifications like ISO 9001:2015, which focus on quality management systems, and IATF 16949:2016, which is specific to the automotive industry. These certifications demonstrate adherence to strict standards, ensuring consistent product quality and regulatory compliance.

Achieving ISO certification involves rigorous assessments that emphasize quality control and continuous improvement. This process boosts a manufacturer’s credibility and signifies a strong commitment to reliability. For industries like automotive, where precision and durability are critical, certifications play a vital role in preventing manufacturing issues such as warping or surface defects.

| Standard | Focus Area | Impact on Reliability |

|---|---|---|

| ISO 9001:2015 | Quality management systems | Ensures consistent product quality and regulatory compliance |

| ISO 13485 | Medical device manufacturing | Guarantees adherence to quality management for safety and reliability |

By choosing a certified injection molding manufacturer, you can ensure your automotive parts meet stringent quality standards, enhancing product integrity and performance.

Production capacity and technology are critical factors when selecting the best plastic injection molding service. You should assess whether the manufacturer can handle your project’s volume requirements without compromising quality. High-capacity manufacturers often leverage advanced machinery and automation to ensure precision and efficiency.

Modern injection molding technology, such as multi-cavity molds and automated systems, enables faster production cycles and reduces costs. Manufacturers with cutting-edge equipment can produce intricate designs with consistent quality, making them ideal for automotive projects. Additionally, you should inquire about their ability to scale production as your needs evolve.

Partnering with a plastic car parts manufacturer that invests in technology ensures your custom injection molding process remains efficient and cost-effective. This approach not only meets current demands but also prepares you for future growth.

Quality control is the backbone of producing high-quality vehicle parts. You need a manufacturer that prioritizes robust quality control processes to ensure every part meets your expectations. Effective quality assurance relies on identifying defects early in the production process. By monitoring critical parameters like injection pressure, flow, and temperature in real time, manufacturers can detect issues such as warping or shrinkage before they escalate.

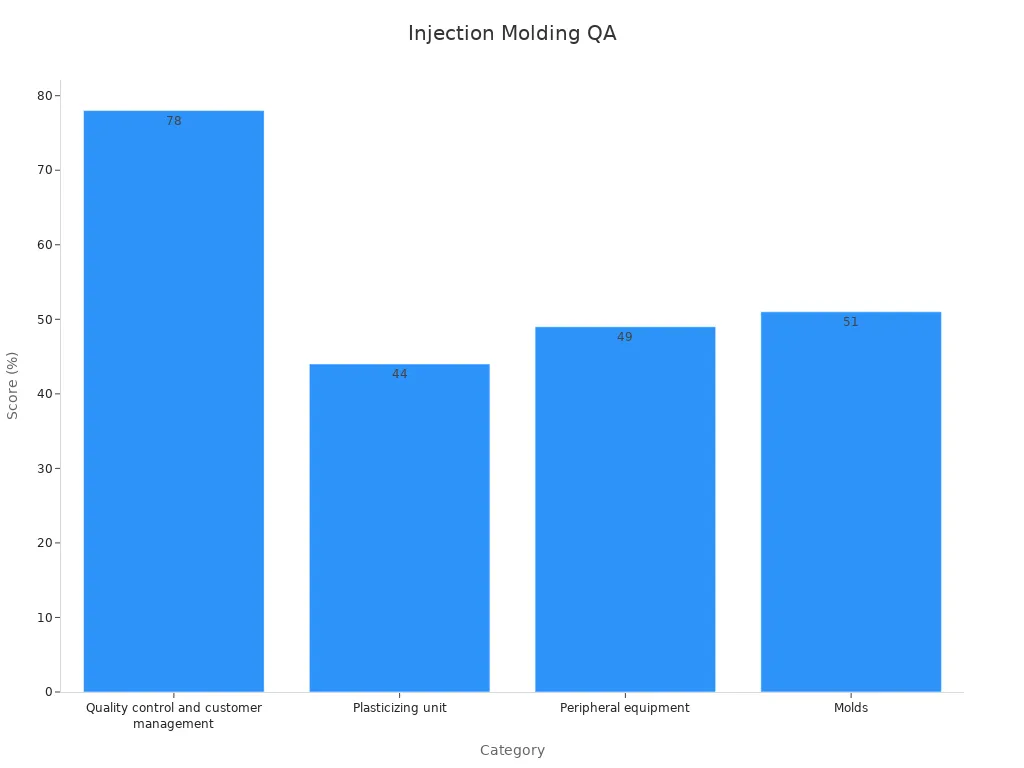

| Category | Score (%) |

|---|---|

| Quality control and customer management | 78 |

| Plasticizing unit | 44 |

| Peripheral equipment | 49 |

| Molds | 51 |

Techniques like Statistical Process Control (SPC) also play a vital role in maintaining quality standards. SPC helps monitor and control variables during production, reducing waste and improving efficiency. For example, univariate SPC models can diagnose process faults and detect defective products with minimal false positives. This ensures that your automotive parts consistently meet performance requirements.

By choosing a manufacturer with advanced quality control systems, you can achieve consistent results and avoid costly production errors.

Certifications are essential for ensuring that a manufacturer adheres to global quality standards. Look for certifications like IATF 16949 and ISO 9001, which emphasize quality management, defect prevention, and continual improvement. These certifications not only enhance product quality but also improve operational efficiency and customer satisfaction.

| Feature/Benefit | Description |

|---|---|

| Improved Product Quality | IATF 16949 emphasizes quality management and defect prevention, leading to higher product quality. |

| Enhanced Operational Efficiency | The standard promotes continual improvement and waste reduction, improving overall efficiency. |

| Increased Customer Satisfaction | By meeting customer requirements effectively, it boosts satisfaction and safety. |

| Global Recognition | Certification is recognized worldwide, enhancing credibility in the automotive industry. |

IATF 16949, based on ISO 9001 principles, includes specific requirements for the automotive sector. It focuses on defect prevention and applies to all companies involved in automotive parts production. A certified manufacturer demonstrates a commitment to quality assurance, ensuring your parts meet stringent industry standards.

Reliable delivery is just as important as quality. A proven track record of on-time delivery reflects a manufacturer’s efficiency and reliability. Key performance indicators (KPIs) like on-time delivery rate, customer satisfaction score, and material utilization rate help measure a manufacturer’s ability to meet deadlines.

A manufacturer with a strong track record ensures your automotive project stays on schedule. This minimizes delays and helps you maintain a competitive edge in the market. Additionally, efficient delivery processes reduce costs associated with inventory management and production downtime.

By partnering with a manufacturer that excels in quality assurance and delivery, you can achieve consistent performance and build long-term success for your automotive projects.

Transparent communication builds a strong foundation for any partnership. When working with a custom injection molding manufacturer, clear communication ensures that your expectations align with their capabilities. Misunderstandings can lead to delays or errors in production, which may affect the quality of your automotive parts.

Effective communication strategies can significantly improve project outcomes:

- Reduce response times by 60%.

- Enhance project visibility by 85% through integrated communication tools.

"Regular audits and detailed reporting build trust and ensure alignment between partners," says a senior operations manager at Global-IMI.

By fostering open dialogue, you can address potential issues early and maintain a trustworthy relationship with your manufacturer.

A trustworthy manufacturer demonstrates responsiveness and problem-solving skills. Quick responses to inquiries or challenges show their commitment to your project. For example, Koller Craft's collaboration with Eaton resulted in a higher-quality product and faster turnaround times. This success stemmed from effective communication and a shared focus on problem-solving.

Manufacturers like BBA and SGM highlight the role of communication in their problem management processes. BBA employs a 14-stage Problem Management Process (PMP), emphasizing communication at every step. SGM uses a more concise approach but still prioritizes effective dialogue to identify and resolve issues quickly. These examples show how strong communication can lead to better control over production and improved operational efficiency.

Long-term partnerships with a trustworthy injection molding manufacturer offer stability and consistency. A reliable partner understands your needs and adapts to your evolving requirements. Online reviews can provide insights into a manufacturer’s reputation and experience, helping you make an informed decision.

Building trust takes time, but the benefits are worth it. A dependable manufacturer ensures consistent quality, timely delivery, and proactive support. This relationship allows you to focus on innovation and growth, knowing your production is in capable hands.

Pricing transparency is essential when selecting an injection molding service. You should evaluate whether the manufacturer provides clear and detailed cost breakdowns. Transparent pricing helps you understand how material costs, mold complexity, and production volume influence the final price. For example, manufacturers often classify molds based on their durability and production cycles.

| Mold Class | Description | Example | Price Range |

|---|---|---|---|

| Class 101 | Highest quality, engineered for over 1,000,000 cycles | Multiple-cavity steel tooling with full automation | Highest-priced |

| Class 102 | Medium to high production tooling, suitable for abrasive materials | Steel tooling with SPI A-2 finish | Reasonably high |

| Class 103 | Rated for under 500,000 cycles | Mold design recommended | Lower price range |

| Class 104 | Rated for under 100,000 cycles | Mold design recommended | Lower price range |

| Class 105 | For prototype purposes only | Cast metal or epoxy | Lowest price range |

Additionally, you should consider value-added services like surface finishing, packaging, and secondary processing. These services can impact the overall cost but may enhance the quality and functionality of your parts. Manufacturers with in-house toolrooms and advanced equipment often offer better pricing transparency and cost efficiency.

Prototyping and design support play a critical role in custom injection molding. Manufacturers offering advanced prototyping technologies can help you refine your designs and reduce lead times. Quick-turn molding solutions, for instance, allow you to test and adjust complex designs rapidly. Similarly, micro-molding and multi-material molding enable precise and efficient prototyping for intricate automotive parts.

Modern tools like rapid tooling and digital mold design further enhance the prototyping process. These technologies enable faster mold production and quick iterations, ensuring your parts meet functional and aesthetic requirements. For example, 3D-printed molds and CNC-machined inserts provide dimensional accuracy while reducing time to market. Collaborating with a manufacturer that excels in prototyping ensures your injection molding service delivers high-quality results.

Choosing the cheapest injection molding service may seem cost-effective initially, but it often leads to hidden risks. Low-cost manufacturers may compromise on material quality, mold durability, or production standards. This can result in defective parts, increased waste, and higher long-term costs.

Instead, focus on balancing cost with value. Manufacturers that invest in advanced technology and quality control processes may charge higher upfront costs but deliver consistent results. For example, top-performing shops produce an average of 82 million parts annually and maintain in-house toolrooms for mold repair. These capabilities ensure reliability and reduce downtime, ultimately saving you money.

By prioritizing pricing transparency, robust prototyping support, and long-term value, you can select an injection molding service that aligns with your automotive project goals.

Selecting the right custom injection molding manufacturer is essential for producing high-quality automotive parts. Defining your needs, evaluating the manufacturer’s capabilities, and ensuring robust quality assurance processes create a strong foundation for success. These steps not only reduce costs but also increase uptime and mitigate risks, as shown in the table below:

| Benefit | Description |

|---|---|

| Cost Reduction | Identifying and eliminating excess inventory to improve Return on Net Assets (RONA). |

| Increased Uptime | Ensuring critical spares are available on-site to support production and maintenance. |

| Risk Mitigation | Identifying risks associated with legacy equipment and planning updates or new production lines accordingly. |

Balancing quality, pricing, and service ensures you make informed decisions that align with your goals. Cloud-based MES solutions, for example, enhance operational efficiency and compliance while optimizing production lines. Building a long-term partnership with a reliable manufacturer fosters trust and stability, allowing you to focus on innovation and growth in the competitive automotive industry.

Custom injection molding is a manufacturing process where molten plastic is injected into a mold to create specific parts. It allows you to produce high-quality, precise components tailored to your design and functional needs. This method is ideal for automotive parts requiring durability and accuracy.

You should consider factors like durability, temperature resistance, and weight. For example, lightweight plastics improve fuel efficiency, while reinforced materials enhance strength. Collaborate with your manufacturer to select the best resin for your project’s requirements.

Certifications like ISO 9001 and IATF 16949 ensure the manufacturer follows strict quality and safety standards. These certifications guarantee consistent product quality, regulatory compliance, and reliability, which are critical for automotive parts production.

Prototyping helps you test and refine your designs before full production. It reduces errors, shortens lead times, and ensures your parts meet functional and aesthetic requirements. Advanced prototyping technologies like 3D printing and rapid tooling enhance precision and efficiency.

Choosing the cheapest option often leads to hidden risks like poor material quality or defective parts. Instead, focus on balancing cost with value. A reliable manufacturer with advanced technology and quality control processes ensures consistent results and long-term savings.